Conception through to fabrication

The Process

The process of building a coffee machine takes several things into account. Where will the machine be used, how often and by whom? It's important to ascertain the basics so the machine will work efficiently for your needs.

A domestic coffee machine will require a different sized boiler and less group heads than a machine being used for commercial use. The placement and size of the coffee machine will need to be considered so it can integrated comfortably into it's new surroundings.

Conceptual Phase

After the initial ideas are finalised I move onto the design phase. Once I have a concept of what I'd like to build, I then start working out what parts I'll need. These are what I call the 'immoveable' parts of the design.

The boiler will be this size, the group head will be this size, the shell will be this material and so on. Once I have the 'immoveables' selected I start working them into the shell design. At this point I then begin working in CAD to provide technical drawings.

Construction

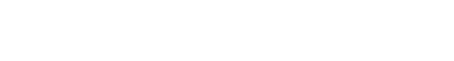

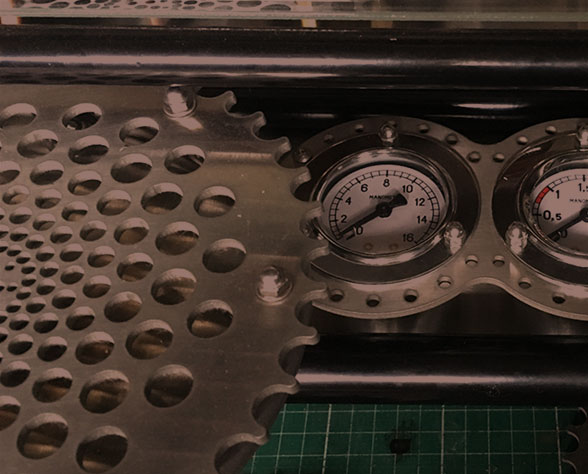

Once the material is cut and shaped for the build, the construction phase starts. This is where all the parts come together which often requires custom machining and tooling to create the individual units. Once the base of the machine is assembled they're plumbed, custom pipe bending and welded fittings are used.

It's then time to electrically wire up the machine, a process that takes considerable time to get looking clean and neat. Lastly the machine is switched on and tested to make sure it's operating correctly and produces beautiful coffee.